A new x-ray microscopy, three-dimensional, quantitative and highly-resolved, x-ray microscopy to explore crystalline nanostructures

Understanding shell growth, controlling the optical properties of semiconductors, or even improving the electrical performance of metallic materials are among the many scientific challenges that require knowing the fine properties of crystals at local scales. Due to their long penetration depth, X-rays allows us to probe the inside of a crystal. But producing a quantitative 3D image - providing crystalline strain field information, for instance - with nano-scale resolution remains extremely difficult as a result of the poor efficiency of the available lenses at these wavelengths.

The new approach developed by a Franco-American team and published in Nature Materials greatly simplifies and speeds up the process.

Over the last several years, a so-called lens-less microscopy has emerged: an image of the crystalline properties is retrieved from the diffracted intensities, and numerical methods are used in place of the lenses. To perform such an experiment, the x-ray beam must be coherent, as in the light delivered by a laser. However, the coherence at even the world’s brightest synchrotron x-ray sources is imperfect, such that the size of the sample that can be imaged with lens-less microscopy is typically of the order of a few microns. This hurdle has been cleared in 2011 by the team of V. Chamard at Institut Fresnel (Marseille, France) by demonstrating the possibility to extend arbitrarily the field of view without degrading the resolution.

This microscopy called Bragg ptychography leverages the spatial dependence of the diffraction patterns measured when a nano-focused x-ray beam is scanned along the sample surface. For each position, the 2D

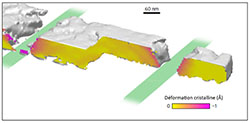

diffraction pattern is recorded. The scanning step, much smaller than the size of the beam spot, produces a strong redundancy in the collected information that enables robust image reconstructions of the sample with new inversion algorithms. Furthermore, three-dimensional information is gained through a tomographic acquisition of the diffracted intensities. Typically, one must measure several hundreds diffraction measurements finely spaced in angle for each beam position on the sample. However, this approach leads to prohibitive total acquisition times (a few tens of hours),

and imposes strong measurement constraints that require specialized experimental set-ups (which only a few beamlines are able to provide), thus preventing the widespread adoption of Bragg ptychography in the scientific community.

The new approach, proposed jointly by researchers from Institut Fresnel (France) and the Argonne National Laboratory (US) greatly simplifies and speeds up this process. Indeed, a huge quantity of information is encoded by the scanning of the beam along the sample, so much so that it becomes possible to perform the measurement at a single viewing angle provided that the intersection between incident diffracted beams is spatially sufficiently well defined. This is indeed the case in Bragg ptychography. The introduction of a modified inversion algorithm gives access to this 3D information in a new and unique way – two dimensions arise from the diffracted signal and one dimension results from the spatial scanning. The new approach, called back-projection Bragg ptychography, marks a conceptual turning point in x-ray microscopy devoted to crystalline materials. The reduction of the total acquisition time, of about a factor 100, and the simplification of the geometry will enable explorations of complex crystalline materials that were not possible to date over a wide range of research areas such as life science and microelectronics.

References :

S. O. Hruszkewycz, M. Allain, M. V. Holt, C. E. Murray, J. R. Holt, P. H. Fuoss and V. Chamard, High-resolution three-dimensional structural microscopy by single-angle Bragg ptychography, Nature Materials 15, December 2016

Contact :

Virginie Chamard, Institut Fresnel, Equipe Comix

ResearchGate

ResearchGate Flux RSS

Flux RSS