We continuously develop laser damage metrology for nanosecond and femtosecond lasers [1-3] and offer laser damage measurements to the industry. Investigations linked to laser damage in crystals for optics (NLO and others) became a kind of specialty of the ILM group and are at the origin of more than 20 publications during the last ten years.

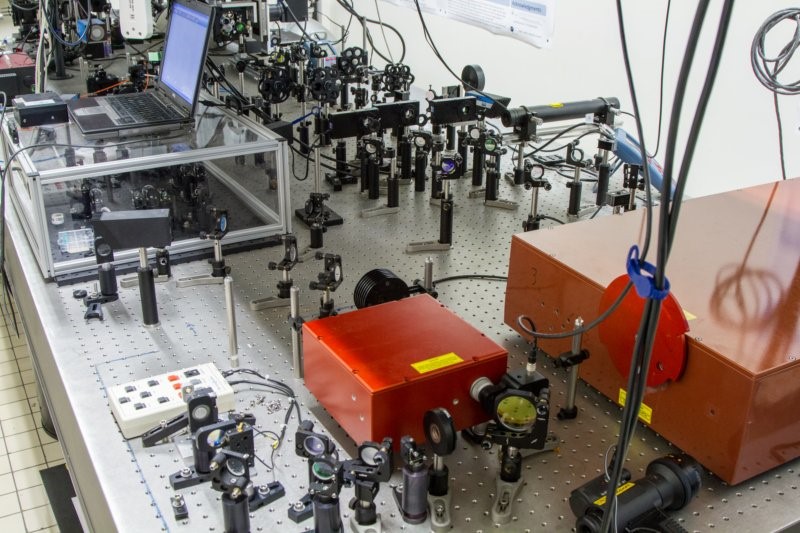

Our measurements are performed on automated laser damage setups using reliable in-situ damage detection [4]. The possibility of reliable in-situ detection opens up the possibility of a detailed analysis of multiple pulse laser induced damage data from S-on-1 measurements [5, 6]. These studies on the fatigue effect in laser damage allowed us to distinguish two different physical mechanisms causing fatigue in the IR (statistical fatigue) and the UV (material modification fatigue).

Working in close collaboration with the CEA we also did some work on the different ways to quantify laser induced damage either in terms of the damage probability in given conditions, or in terms of the damage density at a given fluence.

Concerning nanosecond laser induced damage, we strongly contributed to the development of a model explaining the laser damage probability as the probability of encounter between the high power region of the laser beam and arbitrarily distributed defects in the optical component [7, 8].

References :

[1] F.R. Wagner, A. Melninkaitis, G. Batavičiutė, C. Gouldieff, L. Smalakys, A. Beaudier, J.-Y. Natoli, Characterization of damage precursor density from laser damage probability measurements with non-Gaussian beams, Laser-Induced Damage In Optical Materials: 2015, Boulder (CO, USA), SPIE 9632 (2015) 96321O.

[2] A. Hildenbrand, F.R. Wagner, H. Akhouayri, J.-Y. Natoli, M. Commandré, Accurate metrology for laser damage measurements in nonlinear crystals, Opt. Eng. 47 (2008) 083603.

[3] B. Mangote, L. Gallais, M. Zerrad, F. Lemarchand, L.H. Gao, M. Commandre, M. Lequime, A high accuracy femto-/picosecond laser damage test facility dedicated to the study of optical thin films, Rev. Sci. Instr. 83 (2012) 013109.

[4] L. Gallais, J.Y. Natoli, Optimized metrology for laser-damage measurement: application to multiparameter study, Appl. Opt. 42 (2003) 960-971.

[5] F.R. Wagner, C. Gouldieff, J.-Y. Natoli, Contrasted material responses to nanosecond multiple-pulse laser damage: from statistical behavior to material modification, Opt. Lett. 38 (2013) 1869-1871.

[6] F.R. Wagner, C. Gouldieff, J.-Y. Natoli, M. Commandre, Nanosecond multi-pulse laser-induced damage mechanisms in pure and mixed oxide thin films, Thin Solid Films 592 (2015) 225–231.

[7] H. Krol, L. Gallais, C. Grèzes-Besset, J.-Y. Natoli, M. Commandré, Investigation of nanoprecursors threshold distribution in laser-damage testing, Opt. Commun. 256 (2005) 184-189.

[8] J.Y. Natoli, L. Gallais, H. Akhouayri, C. Amra, Laser-induced damage of materials in bulk, thin-film and liquid forms, Appl. Opt. 41 (2002) 3156-3166.

ResearchGate

ResearchGate Flux RSS

Flux RSS