One of the main limitations of high power laser chains is the problem of the laser damage of the optical components. Different physical phenomena which depend both on the properties of the materials, on their manufacturing / preparation conditions and on the laser irradiation parameters can lead to damage initiation on the surface or in the volume of the components, the damage size increasing upon successive irradiations . This phenomenon limits the increase in power, affects the lifetime of the optical components and the maintenance cost of the laser chains.

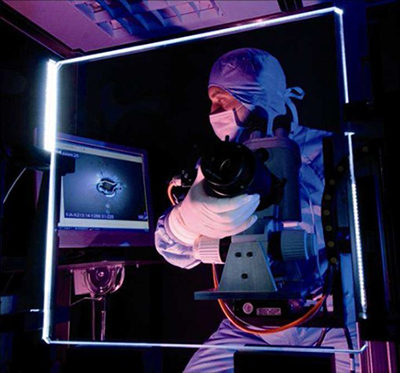

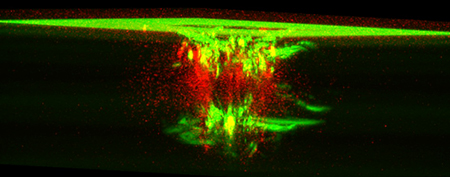

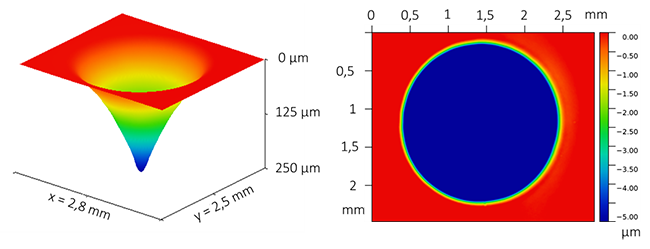

One solution to increase the lifetime of silica components, a so-called "stabilization" laser process is developed at the Fresnel Institute in close collaboration with the CEA CESTA, in the context of MegaJoule laser project . The objective is to treat the damage to stop the growth under repeated shots in order to recycle the damaged optics. This process consists of a fusion, followed by local evaporation, by energy deposition with a focus CO2 laser beam, of the damaged zone of silica. We are particularly interested in the stabilization of laser damage on silica by a micro-machining process based on a rapid micro-ablation of the silica during which the laser beam is scanned on the surface of the component in order to form a crater of adjustable shape (taking into account the deformation of the wave front) encompassing the damaged site. An experimental system is operational at the Fresnel Institute to develop and study this process. Numerical and experimental works are carried out to validate and optimize the technique by studying the physics of the CO2 / silica laser interaction. Other experiments concerning the treatment of fractures related to polishing, or defects in the manufacture of silica networks are also carried out.

Contact : L. Gallais (laurent.gallais@fresnel.fr)

Publications :

Doualle T., Gallais L., Monneret S., Bouillet S., Bourgeade A., Ameil C., Lamaignère L., Cormont P., ‘CO2 laser microprocessing for laser damage growth mitigation of fused silica optics’, Optical Engineering 56, 011022 (2017). Lien sur la revue: http://dx.doi.org/10.1117/1.OE.56.1.011022

Doualle T., Gallais L., Cormont P., Donval T., Lamaignere L., Rullier J.L.,’Effect of annealing on the laser induced damage of polished and CO2 laser-processed fused silica surfaces’, Journal of Applied Physics, 119 213106 (2016). Lien sur la revue: http://dx.doi.org/10.1063/1.4953146

Doualle T., Gallais L., Cormont P., Hebert D., Compis P., Rullier J.L.,’Thermo-mechanical simulations of CO2 laser–fused silica interactions’, Journal of Applied Physics, 119 113106 (2016). Lien sur la revue: http://dx.doi.org/10.1063/1.4944435

Doualle T., Hebert D., Combis P., Hecquet C., Gallais L., Rullier J.L.,’Comparison between fused silica of type II and III after surface heating with a CO2 laser’, Applied Physics A, 120 90 (2016). Lien sur la revue: http://dx.doi.org/10.1007/s00339-016-9606-9

ResearchGate

ResearchGate Flux RSS

Flux RSS