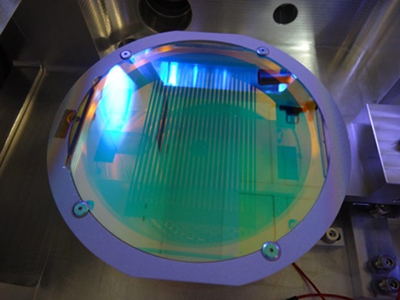

Based on the design methods and the study of refractive index dispersions of materials developed in-house, the RCMO team is specialized in the fabrication of multilayered optical components. These components are made by physical vapor deposition using different machines available in the clean room of the Espace Photonique. The RCMO team has to date:

a Bühler/Leybold Optics HELIOS machine (plasma-assisted magnetron sputtering) associated with an in-situ monochromatic optical control (OMS 5100) and a broadband optical control.

two Bühler/Leybold Optics SYRUSpro 710 machines (plasma assisted electron gun evaporation) associated with a monochromatic in-situ optical control (OMS 5000).

These machines allow the development of a large number of optical components, including:

1. multilayer stacks for space (e.g. bandpass filter with rectangular profile and wide band rejection). These stacks have a large number of layers (more than a hundred per side) and a high total thickness (up to 25 microns and more) which satisfy the particular constraints of space applications. A large number of filters respecting such criteria have been realized (TARANIS, 3MI, IDEFIX projects...) by magnetron assisted sputtering, with deviations between experimental curves and theoretical predictions that do not exceed a few percent over spectral ranges up to 3 octaves. New concepts and components are also studied in the framework of a research and technology project financed by the French National Center for Space Studies (CNES).

2. components for lasers and beam shaping. We are particularly interested in the development of components adapted to high-power lasers in different temporal regimes: from continuous to ultrashort pulses, taking into account both spectral performance and laser flux resistance. Another direction concerns the development of metamaterials or components for laser beam shaping using new materials such as phase change materials or materials with very high nonlinearities. Such components are usually realized on planar substrates but we also realize treatments for guided optics components (OPO, fiber resonators).

3. components for microscopy and imaging. This is a particularly important field in optics which requires the development of components adapted to the specific needs of the measurement systems developed. We are interested for example in the fabrication of new coverslips for fluorescence microscopy (classical or total internal reflection) as well as in the development of calibration slides for these same microscopes. These structures are designed to support either plasmonic or dielectric resonances. Such resonant components adaptable on all types of microscopes, allow us to improve their properties without interfering in the microscope optics.

4. color control by multilayer stacks. This work includes the study of the dispersions of materials in thin layers, in particular metallic ones, and their integration in dielectric multilayer stacks for the realization of colorimetric structures with controlled color variation (whether angularly, thermally, by laser...). The use of these structures, for various applications such as the luxury industry, security elements or design and art is at the heart of our research activities.

Contacts: Antonin Moreau/Julien Lumeau

ResearchGate

ResearchGate Flux RSS

Flux RSS